Belt Monitoring & Rip Detections

Early Detection Systems to Prevent Breakdowns and Damage

Conveyor belts are essential to material handling systems but are vulnerable to damage from splices, steel cord splits, and longitudinal rips—issues that can cause costly downtime, safety hazards, and extensive repairs. Transco Industries provides advanced belt monitoring and rip detection systems to identify these problems early, ensuring operational efficiency and equipment protection. Our solutions extend belt life by detecting weak points like splice deviations or damaged steel cords. Rip detection systems immediately stop conveyors at the first sign of a tear, preventing material loss and costly damage. With belt scanning services, 24/7 support, and expert field teams, Transco keeps your operations running smoothly.

About Coal Control

Coal Control is your specialist in the field of longitudinal slot detection in belt conveyors, steel cable monitoring, splice monitoring and automation technology for the areas of air conditioning technology and underground pump control.

About ROXON

ROXON has specialized in delivering reliable material handling solutions to their customers with maximum productivity through complete systems.

Proactive belt monitoring for safe, efficient, and reliable operations

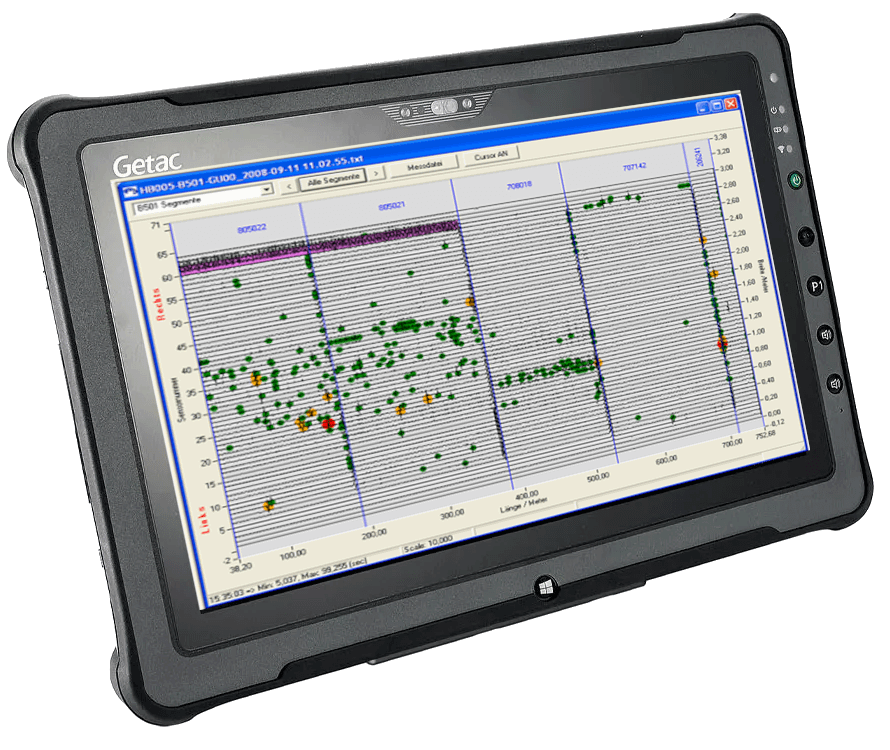

Splice Control

Splice Control is a computer-aided system that monitors conveyor belt splices with precision. Using embedded magnets and magnetic-field sensors, it detects changes in splice conditions during each belt rotation. It ensures early problem detection, minimizing costly ruptures and downtime in mining, ports, and power plants.

View CC040x Datasheet View Technical Information

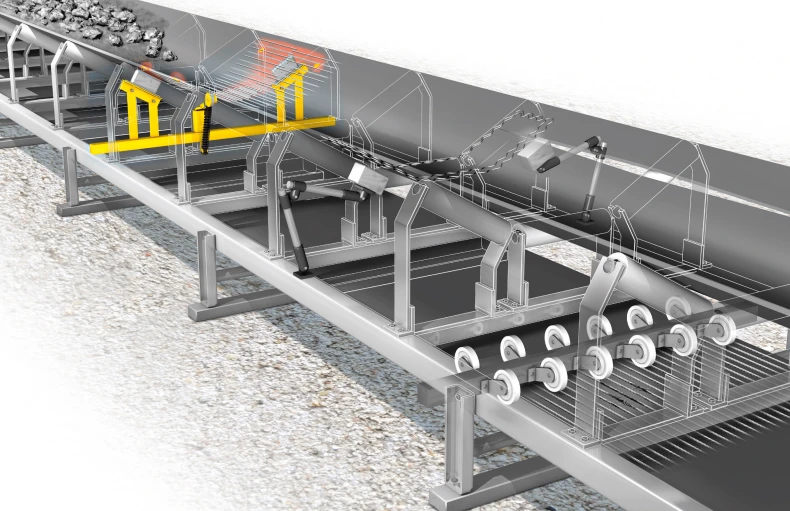

Rip Detection

Rip Detection systems protect conveyor belts by identifying longitudinal tears in real time. Sensors and automated stop mechanisms immediately halt operations to prevent further damage. Perfect for high-capacity systems in mining, sand, and gravel, Rip Detection enhances safety, reduces material loss, and protects critical equipment.

View CC0204.2 Datasheet

Cord Monitoring

Cord Monitoring uses advanced sensors to evaluate steel cord conveyor belts for splits, fractures, and wear. Offering real-time diagnostics, it prevents failures and minimizes downtime in industries like mining, power generation, and ports. This proactive solution extends belt life while supporting reliable, uninterrupted operations.

View STA-CC0350 Datasheet View Technical Information

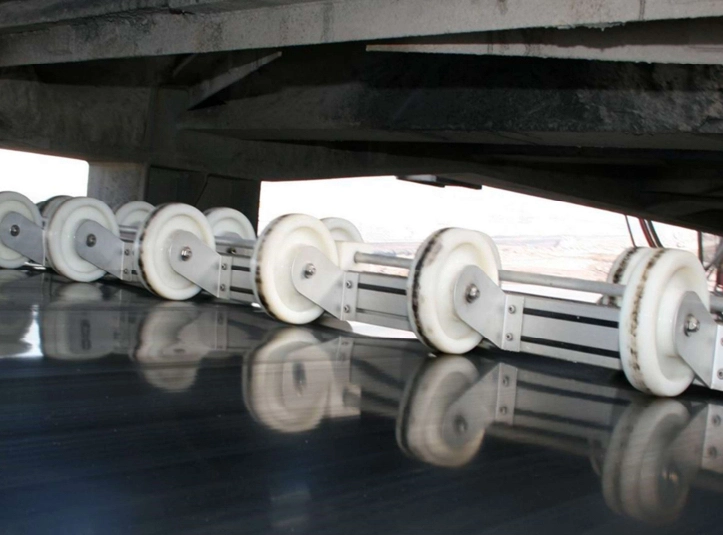

Mobile Cord Watch

Mobile Cord Watch delivers portable monitoring for steel cord belts, using compact magnetic sensors for precise diagnostics. Installed on the belt's return side, it provides flexible deployment and real-time data during operations. Ideal for mining and construction, it ensures belt reliability across multiple systems with ease.

Let's Keep You Moving

Ready to boost your productivity or solve operational issues? We're here to help—reach out today.

Contact Us